# Single File Manufacturing

Talking about how the next Industrial revolution will be.

- Complexity in manufacturing and design is free

- No assembly required

- Zero lead time.

- Zero skills required for manufacturing

- Compact, portable and decentralized manufacturing

- No waste by-product

- Infinite material options

- Precise replication

- All knowledge combined into one single, exchangable and digital file

- no cost differential between single piece or mass production

I will start this discussion about how our brain works and how ideas are constructed and copied.

# Memes

A meme is like a word and when connected they shape new sentences. Connected sentences create stories. Stories create books. Books create religions and religions create meaning. Memes are the smallest pieces of information that can be connected in some order to create ultimately something meaningful.

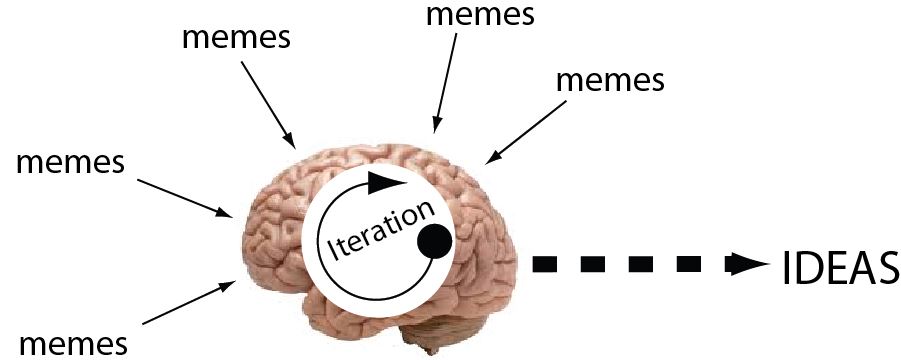

I see the brain as a meme construction device. Apart from motion control and managing all other internal function the most important function for the brain is connecting these small meme-bricks into new complex systems.

When we are 'creative' we actually connect all these memes-bricks from the outside world with memes internally stored in our brain into new ideas. And because we can have internal discussions with our self we can iterate a bit with these thoughts. With our internal voice / thoughts we can construct new idea systems without any consequences and test them with the feelings we get from them or compare them with other ideas we already gathered. Thinking is an internal iteration process. Literally 'thinking is designing'.

Creative people are highly capable of adding and subtracting memes into new systems, or even systems of memes into more complex systems. This implies that even though you think you have a genius idea your idea had its predecessors. Meaning it is impossible to have new ideas without the input of your environment. Creative people are just better to use their 'meme construction device' / creative capability of their brains. They can combine seemingly unrelated meme-bricks from different fields into one new coherent idea. Visionaires on the other hand are those who do not create new ideas per se but understand what an idea actually means for the future of society.

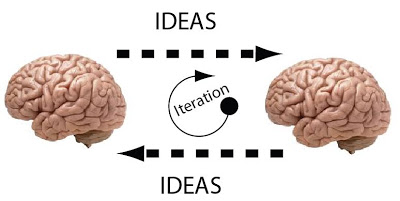

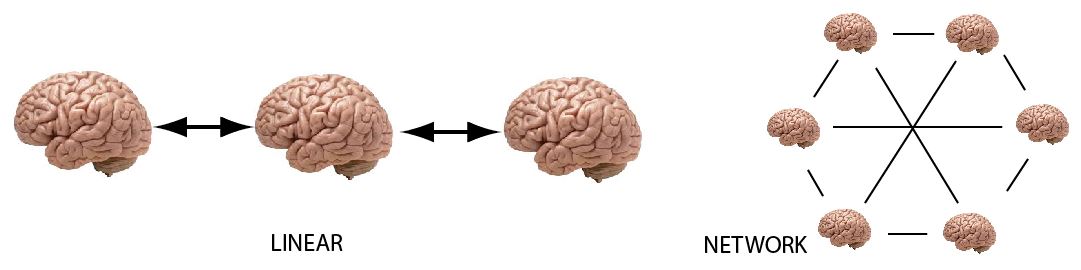

When we create a new idea, constructed from smaller memes, we can share this idea with others. Sharing means that we actually copy this idea from our brain into other brains who can copy it to others. By doing so multiple other brains will iterate / build upon our first idea. This sharing process between group members can be done linear, from generation to generation, like a folk story, or in a network like in a gossip. You can imagine the more and more connections the more iterations and the more variances and specialties will evolve from small mutations in the original idea.

I believe technology is a materialized form of memes. If you look to a piece of technology you will see thousands of little ideas combined into one piece of working hardware. To create a single laptop we had to build upon thousands of years of simple ideas that created more complex ideas that were used as building blocks for even more complex ideas.

In the past the only way to copy a piece of technology, let's say a stone tool, was literally by creating a tool straight from memory gained from life experience. So a copy from brain-memes to materialized-memes. In the past memory was therefore very important. If it wasn't for language the death of the toolmaker would also imply the death of someone's skills and ideas. The reason why we humans are so successful with tools is because we were starting to share our ideas by language. As I already explained by talking about an idea, in this case a stone tool, we would copy our ideas into someone else's brain. A tool maker can pass on the knowledge about the tool by explaining 'how to' to his son, so he could create it again with the ideas of his father from memory.

I believe that human technological progress goes hand in hand in the way we copied memes. After language we created drawing. Instead of demonstrating the tool or talking about it we could pass on the knowledge with a drawing and later with written words. And above all with these new mechanisms memes were stored on something 'infinite' ours. With drawings and written word our ideas could replicate and spread all over the world.

# Copy mechanisms

Our next big evolutionary step was about copying again. Instead of manually copy word after word a book-printer device would copy books, papers, stories, ideas, memes at low cost and faster than ever before. We became better and better in copying ideas.

As you probably already have noticed 😉 we live right now in the 'information age". We created the digital version of ideas and connected them through the internet. This is 'The biggest step in history' about how ideas are being iterated and copied. Information is abundant because sharing and storing ideas can be done at practically zero costs. If technology is materialized memes a complex technology constructed of thousands of little ideas could be copied digitally with one simple click. Our brain is created to replicate memes and by our tools we became even better in replicating ideas than nature itself.

One big question remains: What would be the next step in the evolution of meme copying for technology? Can we digitize all memes needed to copy technology? What would be the most efficient way we can copy technology? I guess the copy process requires digital tools and it is done with one click. Maybe even less. In other words what would require to copy ALL the knowledge needed to create an exact copy of something? This is the holy grail in our copy quest....

# Materialisation

There is a big important difference between the part that copies and the part that materializes. Memes can be transformed into different forms similar to energy conversion. We have kinetic energy, electric energy, heat energy etc. To gain heat energy one could transform wind energy, into kinetic energy, into electric energy, into heat energy. To create a wheel, we can translate brain memes (thoughts) into written memes (tech drawings), into digital memes (scanned image), into written memes again (printed tech drawing), into materialized memes (wheel). As I stated before technology is materialized memes and memes form the smallest unit we use to describe ideas and thus technology.

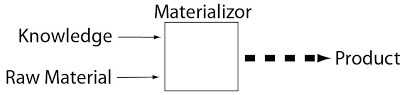

If we would copy a piece of technology we would always first convert the technology into an other meme form, like a technical drawing, a mental image, spoken word or a digital scan before we would actually materialize it again. It is impossible to copy technology without first doing some meme conversion. As I told before memes are the parts that copy. Memes are the replicators. Tools like pencils, printers, milling machines, laser cutters can transform ideas into matter. I would call these kind of tools the materializors.

A materializor is seldom a single tool but would rather be a combination of different tools with the knowledge of using that tools. If you want to materialize your technical drawing of a bicycle design for example into a working piece of hardware your design is likely to go to a welding service equipped with all kinds of special tools for cutting and welding the frame tubes together with a lifetime knowledge of using them.

This extra knowledge apart from the initial design ideas makes materializing difficult. With my first business I noticed how difficult it was to be sure that the materialization of your design was exactly the way you invented. Three reasons:

- The workman changed the design in his favor to make it more make-able according to his way of making.

- The design changed by machine capabilities and settings unknown to you.

- The design described by the technical drawing and cad files didn't cover the TOTAL design

A good technical drawing is like a contract. It says exactly what the workman should create within certain boundaries. If he isn't able to materialize the design with his tools and knowledge he shouldn't sign up for the contract. The technical drawing is the single file the workman need, but without his special knowledge and tools it is impossible to create the piece. And the fact that this extra knowledge is not within the design file makes the difference between now and the Next Industrial revolution.

Think of CNC milling machines, laser cutters, water, cutters etc etc. These devices are highly capable to materialize designs. I have gained much experience with laser cutting tools for flat parts and even tubes for the design of cargo bikes (www.vrachtfiets.nl). I often send a single digital file to a local laser cutter where an operator could create the piece in steel. I discovered many many small companies with laser cutters and other CNC tools to materialise designs, because CNC subtractive manufacturing is already spread around the world.

If we would print an email with different printers the text and images would always slightly differ by an infinite number of small causes. The mutations of the print caused by random forces are within certain boundaries. But if we would print the email, scan it and print it again it would ultimately create an unreadable result. On the other hand if we would send an email to somone who would send it again and again and again... receivers would all still be able to read it. No special knowledge or skills are required to create perfect copy-able emails. Just hit send!

If I have to design a simple business card holder from laser cut aluminium I would send a digital file to what ever city and materialize it locally next to the doors of my customers. The big problem however is that a business card holder is pretty easy to design and I actually don't care about the little changes the local company did. But when design complexity increases the smaller details matter as well, and therefore I need to be sure that the local manufacturer shares the same "handbook for materialisation" as I do. Else things can go wrong quite easily. Think about material use, unknown temperature influences, parts from other suppliers, assembly, communication problems, etc etc. Therefore we often opt in for a test production batch.

# Future

In the world of single file manufacturing all the knowledge needed to create a product is stored within that file and no extra human knowledge is needed to materialize that digital copy. No unknown local machine settings or whatever will change the design more than the predefined tolerances. If we would be able to create really single and digital file manufacturing the TOTAL copy of the knowledge required to materialize a design is free. Materializing can be done at any place by any person, because you don't need special knowledge or skills to materialize designs.

We could set up small factories in poor countries to materialize rich designs for local needs. Or skilled but from devoloping countries could create amazing stuff materialized in the West. Intensive sharing programs could be started to iterate solutions for whatever problem and from wherever. As a designer and entrepreneur I would travel to cool places of the world with my laptop and design tools and create amazing stuff that will be materialized somewhere exactly the way I have imagined. For me this image is the 'Next Industrial Revolution'.

I personally do not think this revolution is about 3D-printing, although it can play a role. We live in an area where everything has the tendency to become more and more digital. If you nowadays visit a local furniture maker they probably have 9 out of 10 times a CNC milling machine. Even craftsman starting to use digital manufacturing tools. Although these tools still have their limitations I am sure we can create single file manufacturing by simple creating better ways to store knowledge. Thus what we need for the next Industrial Revolution is not a 3D-printer but a modern file standard!

The Next Industrial Revolution will be about:

The PDF standard for production.

And yes as with all standards there will be a war about who defines that standard....so let's start.