# VFA Solutions

VFA Solutions is a small but innovative company from Schiedam The Netherlands that developes and produces air purifiers for mainly the industrial and utility sector. As an engineer I did a wide variety of interesting projects in my full time position at VFA (current position). In this article I will discuss a few of them.

# Aspra PMC

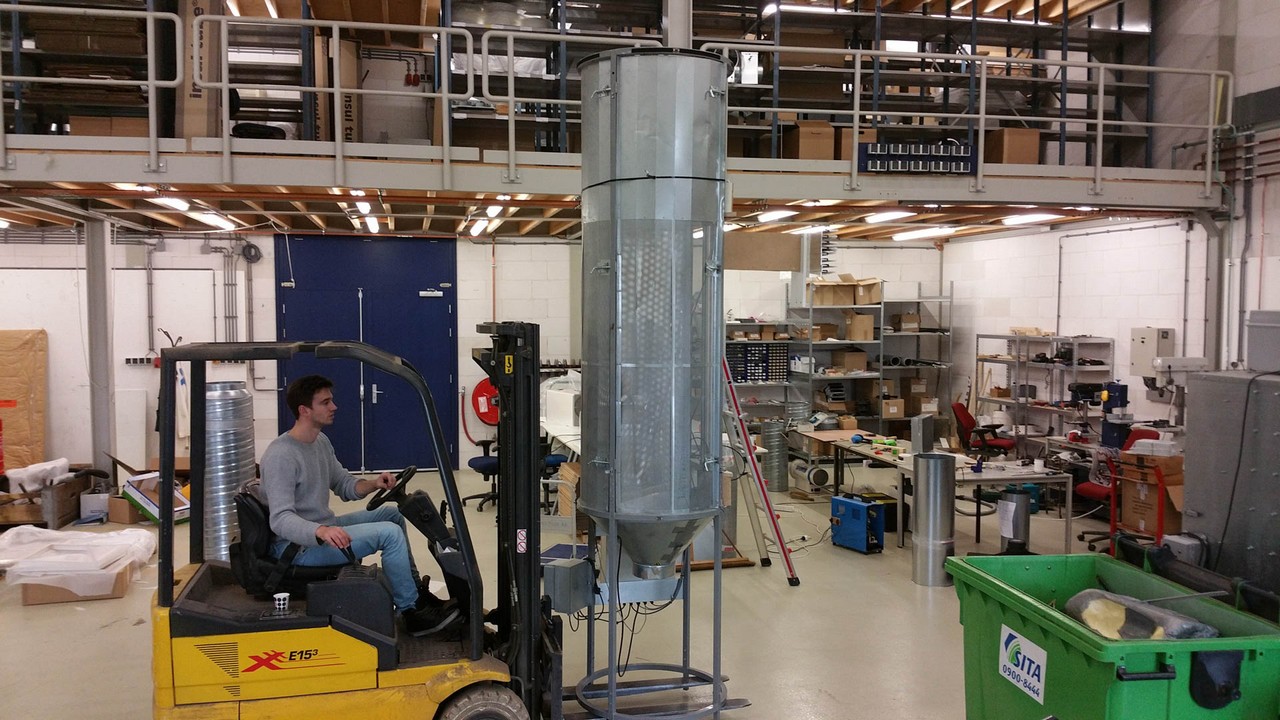

The PMC (Particle Mass Cummulator) is a 10.000m3/h air purifier developed for warehouses, industrial plants, distribution centres etc. When I started at VFA this was my first assignment.

I came to work at VFA just at the time they wanted to broaden their scope to bigger and more industrialized markets. The Aspra PMC started as a concept that would be the biggest product so far for VFA, and would combine knowledgeand tests from previous projects done by my colleagues. Before the development of the Aspra PMC my colleagues engineered and build a batch of prototypes for the agricultiral sector, which I used as a starting point for the Aspra PMC. I had to solve many of the early prototype issues, make it suitable for a different sector, and extend it feature capabilities. Basically I was requested to redesign the whole damn thing into real sellable product!

The working principle behind the Aspra PMC is called the 'ASPRA-technology'. The PMC is in that respect quite similar to smaller VFA products, however the PMC utilizes a seperated filter for course dust with an unique self cleaning brushing mechanism (bigger particles), combined with a seperated filter for fine dust. The main promise of the PMC is to clean large volumes of air at minimal operating costs.

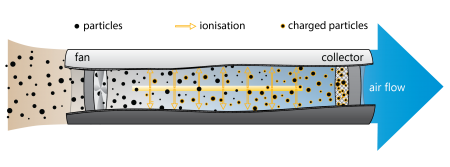

The basic filter solution is very simple: the smaller the particles you want to catch the smaller the pore sizes of a filter has to be. Filters have different classes depending of how fine the pores are. However filters with smaller pore sizes require more powerful fans to push the air through, or in other words consume more energy. Therefore the extra energy required with traditional filters is especially for industrial applications significantly. To solve this the Aspra technology utilizes a technology called 'electrostatic precipitation'. With this smaller particles can be caught with bigger pores. This works by adding a static charge to particles, so particles get littarly attracted to the filter medium, instead of caught by the different pore sizes. With this the Aspra technollogy is really suited for applications where large volumes need to be filtered efficiently; hence the PMC !

The first version I created was tested at a boulder center in Delft. In the boulder center they use oxidised magnesium for extra grip during climbing. Imagine a room covered with layers of magnesium dust. It is everywhere. And although with the use of the PMC not all the dust goes completely away, when the PMC is turned off everybody notices a real differences.

The second batch of Aspra PMC's for a distrubution centre with of course many small and a few big improvements.

# Aspra Agro

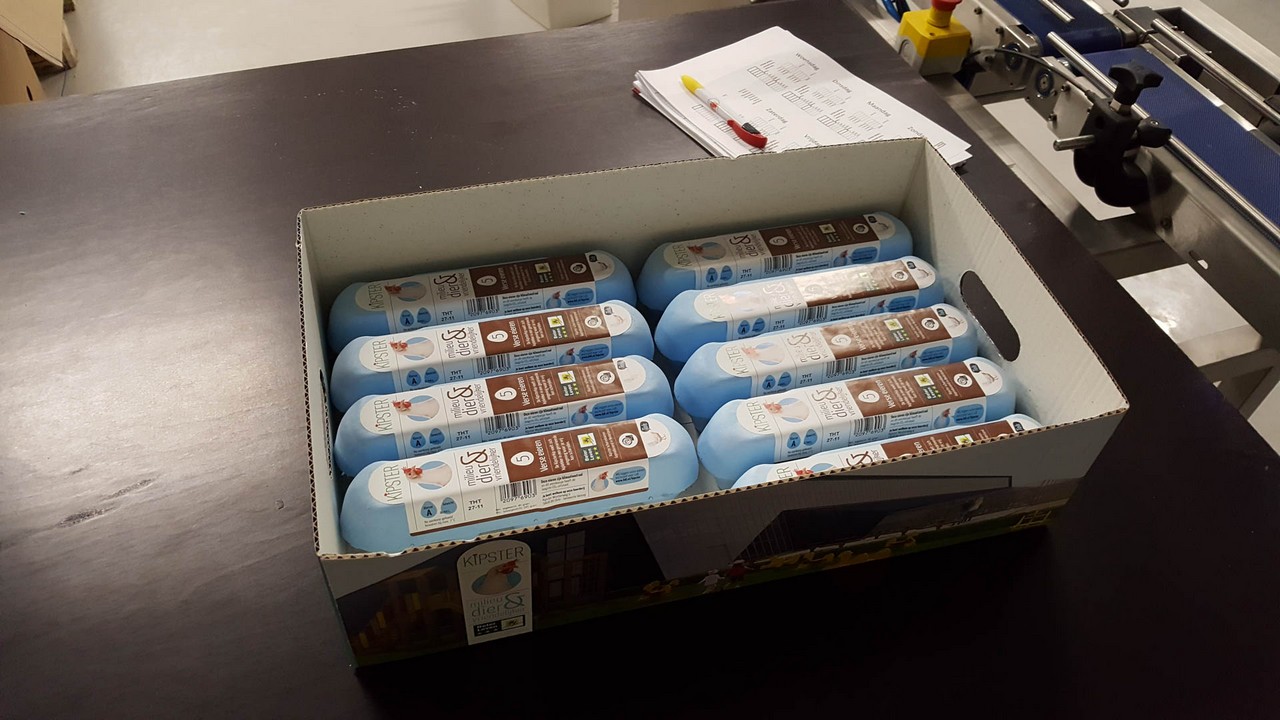

For the Aspra Agro I kind of re-engineered it back so it could be used for agricultural areas (reverse-re-engineering? 😉) This time for the most sustainable chicken house in the world: Kipster (opens new window) ! I see Kipster as a playground for chickens, and is in many ways the future of the modern and animal friendly chicken house. Interestly enough they were also interesed in the air purification of the future... my design 😉 ... brag brag. It is not entirely my design of course, because I did only the construction, but still, it was very cool to participate in a meaningful project like this. Even more awesome is it when you see the end result of this in a regular supermarket.

The Lidl supermarket sells Kipsters eggs in the Netherlands in blue boxes. I sometimes buy them. They are on average a bit smaller but the taste is very good.

In a chicken house it is normally very dusty. The dust is mainly created by chicken shit....yeah it is what it is. Especially in a chicken house where chickens can flutter around dust is everywhere. The dust (...) is not good for the chickens themselves, for the farmers and also for surrounding residential areas. Besides that governments are implementing more and more regulations about emissions for chicken houses. Thus the Aspra Agro is an interesting development for the sector.

Basically the Aspra Agro is the Aspra PMC without its surrounding construction. They both share the same components. The version you see depictured above has two plastic bags that agregate the collected dust, new version use solid bins so chickens cannot puncture the bags.

During its initial phase we improved uppon some points. It is by the way quite bizar to be un such a chicken house.. especially for such a city boy like me.

# BMC Moerdijk

More chicken shit! The BMC project is as far as I know the next level regarding chicken shit. And hopefully also the final level, oeps 😉 So we have 100.000.000 chickens in The Netherlands, and they all poe. Let that sink in....

BMC is a company that basically collects nationally all the chicken shit and burns it. It produces on the end of the process more energy than it requires. By doing so it earns money from the energy, the farmers have to pay, and I even believe they are subsidised by the goverment. So that sounds like a proper business model to me! This legal money press machine stinks however in a totally different extraordinairy terrible way! Luckely for me and my colleagues VFA Solutions created a solutions for them (...), yikes.

With VFA Solutions we implemented two huge airfiltration systems on the roof. It has multiple stages inside. I helped with the basic layout of the system and one of the filter stages.

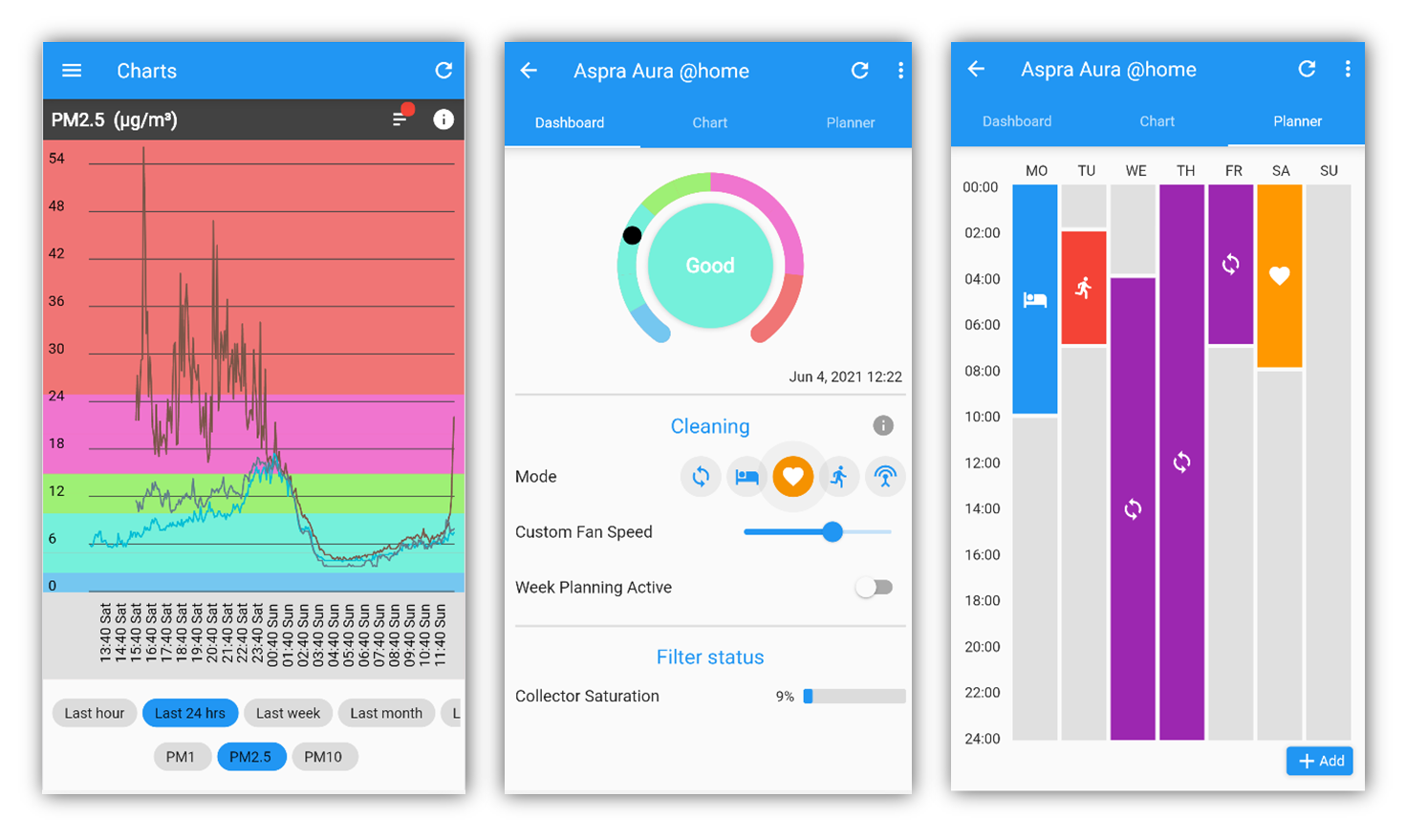

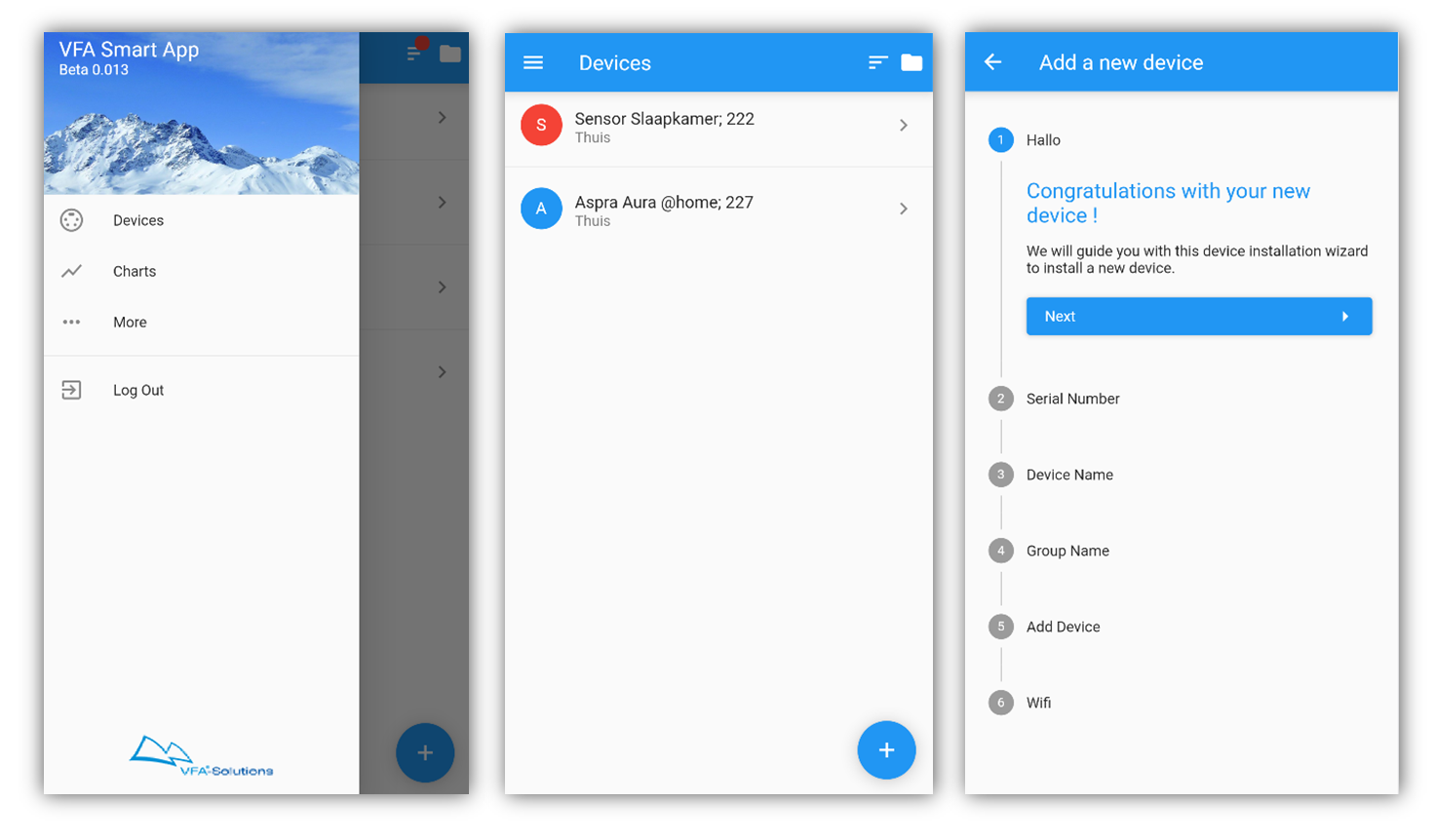

# Smart app for sensors and air purifiers.

For this project I used a totally different skill namely programming. Programming is a long lived a hoby of me and I was very pleased I could practice that for a real commercial project here. The app is build with Dart/ Google Flutter (opens new window) for multi-platform usage: web, desktop, IOS and Android.

With this app users can add, manage and read VFA's particle sensors and air-purifiers. Next to the interface design and app coding I also conceptualised the API-requests (opens new window). The actual server is developed and maintained by another company. Furthermore I designed and developed a web-based backend tool for my collegea's in Vuejs/Nuxtjs (HTML, CSS, Javascript). This tool helps with managing things like device types, region settings, and serial numbers etc